How to Identify a Failing Pin Connector and What to Do About It

Electrical problems in vehicles can frequently be traced back to a single source: a faulty pin connector. These little yet critical components ensure proper communication between a car’s numerous systems. When they fail, it can cause a chain reaction of problems, from faulty sensors to entire systems shutting down. Early detection of these issues is critical for collision specialists and automotive professionals since quick intervention can save costly repairs and downtime.

In this blog, we’ll explore the critical signs of a failing electrical connector, share practical troubleshooting steps, and discuss the benefits of working with a connector specialist like FindPigtails.com. Let’s dive in and learn how to handle these challenges effectively.

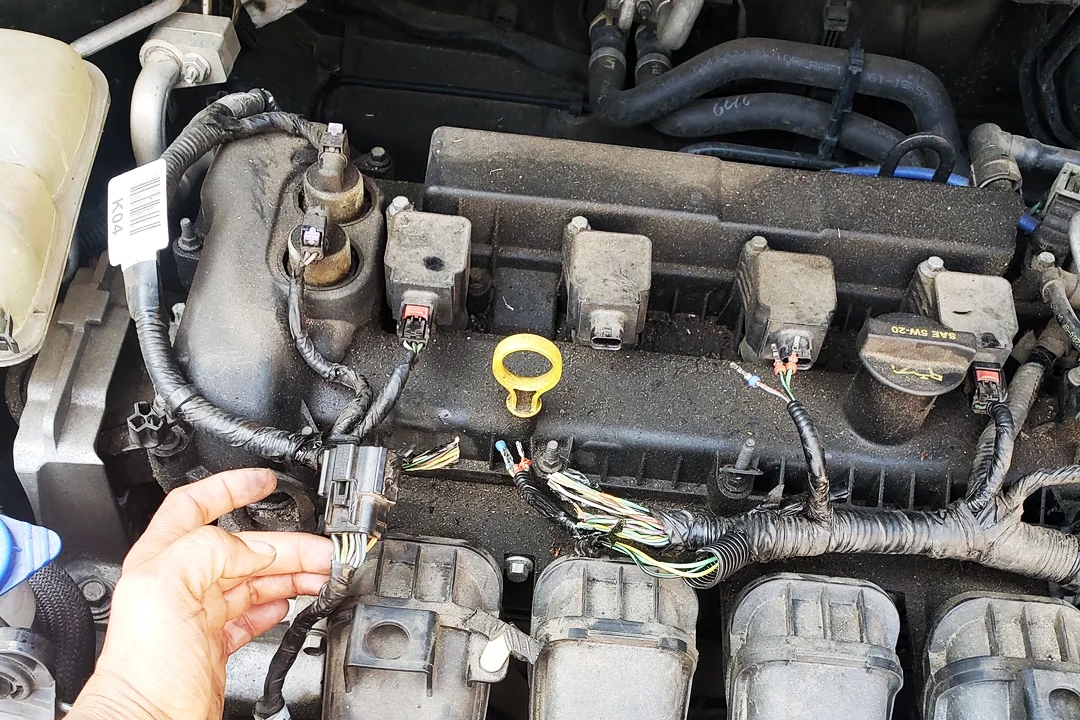

Signs of a Failing Pin Connector

If you know what to look for, you can quickly identify the symptoms that failing automobile connectors frequently display. By recognizing warning signs like noticeable damage or loose connections, you can prevent further electrical failures.

Symptoms Indicating Connector Problems

Before you start troubleshooting, it’s crucial to determine if the connector is the source of the problem. Look out for the following typical indicators:

- Intermittent Electrical Failures

Flickering lights, malfunctioning components, or sensors providing inconsistent readings often point to a weak connection caused by a failing pin connector. - Visible Damage

Check the connector’s housing and pins for cracks, corrosion, or discoloration. Bent or broken pins are a sure sign that the connector needs attention. - Loose Fit

A secure connection is critical for proper function. If the connector feels loose or moves when tested manually, it may not be properly seated or damaged. - Unusual Odors or Heat

Burnt plastic odors or excessive heat near the connection point may indicate an electrical short or damaged insulation in the connector.

Each of these symptoms can provide valuable clues during your diagnostic process.

Tools to Inspect a Pin Connector

The right tools are needed to conduct a comprehensive inspection. Having these on hand guarantees you can quickly determine the issue without further damaging the connector.

- Multimeter

Use this essential tool to check for electrical continuity and ensure power flows correctly through the pins. - Magnifying Glass

Closely inspect pins for damage, corrosion, or misalignment. Even minor imperfections can lead to significant issues over time. - Contact Cleaner

Remove debris and oxidation from the pins, as well as connection points, to restore conductivity.

Using the correct tools ensures an accurate diagnosis, reducing the chance of misidentifying the problem.

Featured Repair Tools

Steps to Address a Failing Pin Connector

After confirming the connector is the source of the problem, decide on the next steps. Some issues can be resolved through cleaning and troubleshooting, while others may require a complete connector replacement.

Basic Troubleshooting Steps

For minor issues, follow these steps to restore the connector’s functionality:

- Clean the Connector

Over time, dirt and oxidation can accumulate on the pins, causing poor connectivity. Use a contact cleaner and a soft brush to remove any buildup. - Test the Connection

Use a multimeter to ensure the connector is delivering power correctly. Check for voltage drops or breaks in continuity. - Secure the Fit

Ensure the connector clicks firmly into place. Replace any broken or missing clips that may prevent a tight connection.

These steps can resolve the problem quickly and effectively for most minor issues.

When to Replace the Connector

Sometimes, cleaning and troubleshooting aren’t enough. Here’s when you’ll need to consider a replacement:

If the connector shows extensive physical damage, such as melted plastic or broken pins, it’s time to replace it. Electrical testing that reveals a complete loss of continuity is another clear indicator. Additionally, replacement is the best solution if the connector repeatedly disconnects or fails to maintain a stable connection. Always choose high-quality connectors that meet manufacturer standards to ensure durability and long-term reliability.

Featured Video: L72A8 Automotive Connector Depin and Repin

Why Work with a Connector Specialist?

Pin connectors are essential in automotive systems, but not all are created equal. Working with a pigtail expert can save you time, reduce errors, and ensure you use the right part for the job. A connector professional can help you find the correct connector for your vehicle’s make and model, guide you through installation, and give valuable advice on connector maintenance and repair. Access to expert knowledge can make a huge difference when dealing with complex automotive systems.

Find the Right Automotive Connector at FindPigtails.com

At FindPigtails.com, we understand the challenges of diagnosing and repairing failing connectors. We have created a platform that simplifies finding the right automotive connector. Our user-friendly search tools allow you to find the right match by vehicle, keyword, or photo. Our team of professionals is also available through live chat to provide real-time assistance and recommendations. Visit FindPigtails.com today to explore our extensive inventory of high-quality connectors, confidently meet your repair needs, and quickly return to work.

Fernando is a seasoned professional with more than 10 years of experience in the e-commerce industry. He has a strong interest in the automotive sector and a strong desire to keep up with technological advancements. He is a priceless asset who helps customers succeed by lowering their cycle time and severity thanks to his extensive knowledge of ecommerce, automotive connectors and professional experience in the field.