The Hidden Role of Connectors in Vehicle Safety Systems

When drivers think about safety, they picture airbags, seatbelts, and anti-lock brakes. But behind every one of these critical systems is something more minor and often overlooked: electrical connectors.

These connectors may not get the same attention as modules or sensors, yet they serve as the lifeline between components. A faulty or corroded connector can cause warning lights, false diagnostic codes, or even turn off a safety feature entirely.

This post explores connectors' hidden role in airbags, ABS, ADAS, and more, as well as what collision repair technicians should look for during repairs.

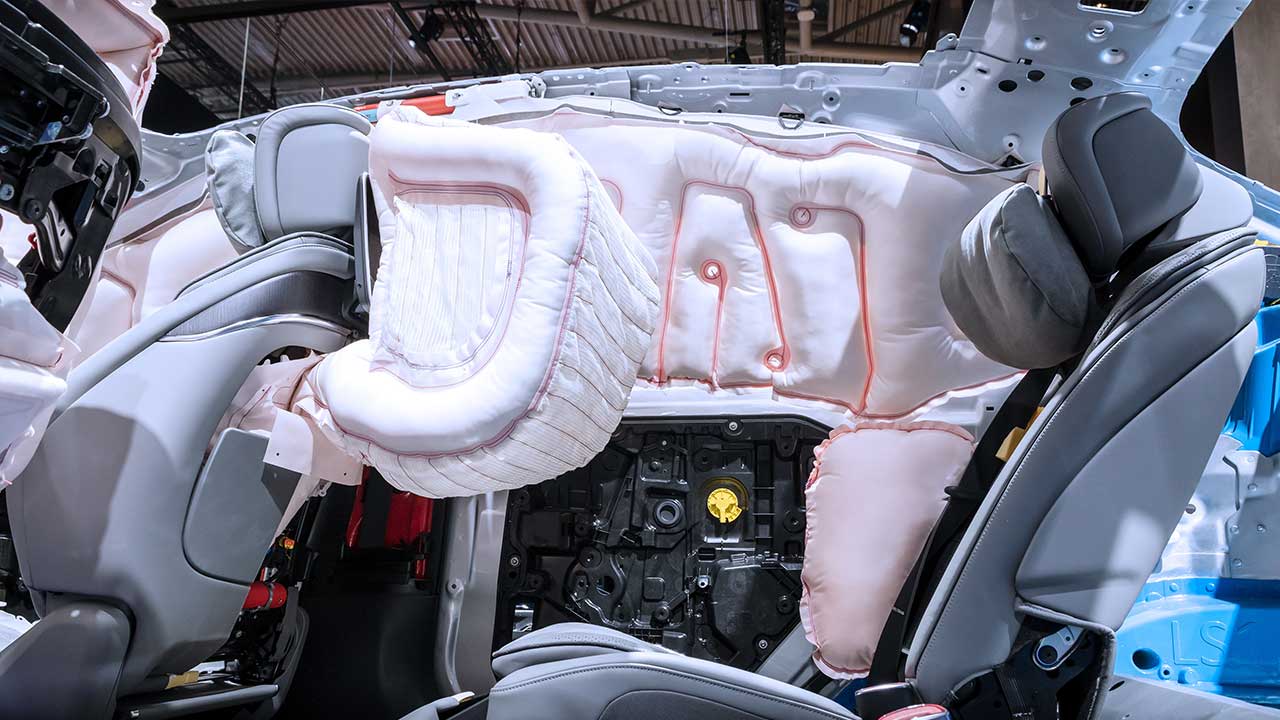

Airbag Systems (SRS)

Airbag deployment depends on a reliable network of sensors, inflators, and control modules. Connectors are the critical link between these parts.

- Why they matter: If an airbag connector is loose, corroded, or misaligned, the system may fail to deploy in an accident.

- Common issue: Under-seat or under-dash connectors are especially prone to damage and often trigger SRS lights.

- Repair tip: Always inspect these connectors before replacing costly airbag modules.

ADAS and Driver Assistance Systems

Modern vehicles rely on cameras, radar, and ultrasonic sensors for lane departure, blind spot monitoring, and collision avoidance.

- Why they matter: These sensors are useless without properly sealed connectors transmitting accurate data.

- Common issue: ADAS connectors are sometimes left loose or misaligned after bumper or mirror repairs.

- Repair tip: Always reseat and test ADAS connectors during reassembly to prevent calibration failures.

Seatbelt Pretensioners and Occupant Detection

Pretensioners and seat occupancy sensors are tied directly to under-seat connectors.

- Why they matter: If a connector is disconnected or corroded, pretensioners may fail to activate or sensors may misread passenger presence.

- Common issue: Spilled drinks and water intrusion quickly damage these connectors.

- Repair tip: Any SRS or seatbelt code should trigger an immediate inspection of under-seat connectors.

Overlooked Safety Components

It's easy to focus only on airbags and ABS, but connectors also affect everyday safety.

- Lighting: A corroded headlight or side marker connector can reduce visibility at night.

- Windshield wipers: Even a failing windshield wiper motor connector can put drivers at risk in heavy rain.

- Powertrain systems: Issues aren't limited to safety — damaged connectors in modules like the transmission control module can create drivability problems that indirectly affect vehicle safety.

Common Connector Failure Points

Across all safety systems, technicians see the same issues:

- Moisture and corrosion in exposed connectors

- Vibration loosens pins or housings

- Repaired with "universal" parts that don't meet OEM standards

- Broken or missing seals that allow dirt and water to enter

Why Shops Can't Overlook Connectors

For repair shops, overlooking a corroded connector isn't just a missed diagnosis; it's a comeback waiting to happen. The most minor electrical fault, from ABS lights to airbag malfunctions, can damage trust and profitability. Thorough connector inspection should be part of every diagnostic process, especially when dealing with safety systems.

Small Parts, Big Responsibility

Vehicle safety relies on more than modules and sensors. From airbags to headlights, automotive connectors are the hidden links that keep these systems working.

By inspecting, repairing, or replacing faulty connectors, technicians can prevent costly misdiagnoses, improve reliability, and protect customers on the road.

At FindPigtails.com, we carry a wide range of OEM-quality automotive connectors and pigtails for safety-critical systems, from ABS sensors to windshield wiper motor connectors. Whether you're working on collision repair, diagnostics, or module replacement, we help you find the right part fast.

👉 Shop automotive connectors today and keep your safety repairs reliable.