Chasing Ghosts: A Pro’s Guide to Diagnosing Intermittent Faults with Pin-Fit Testing

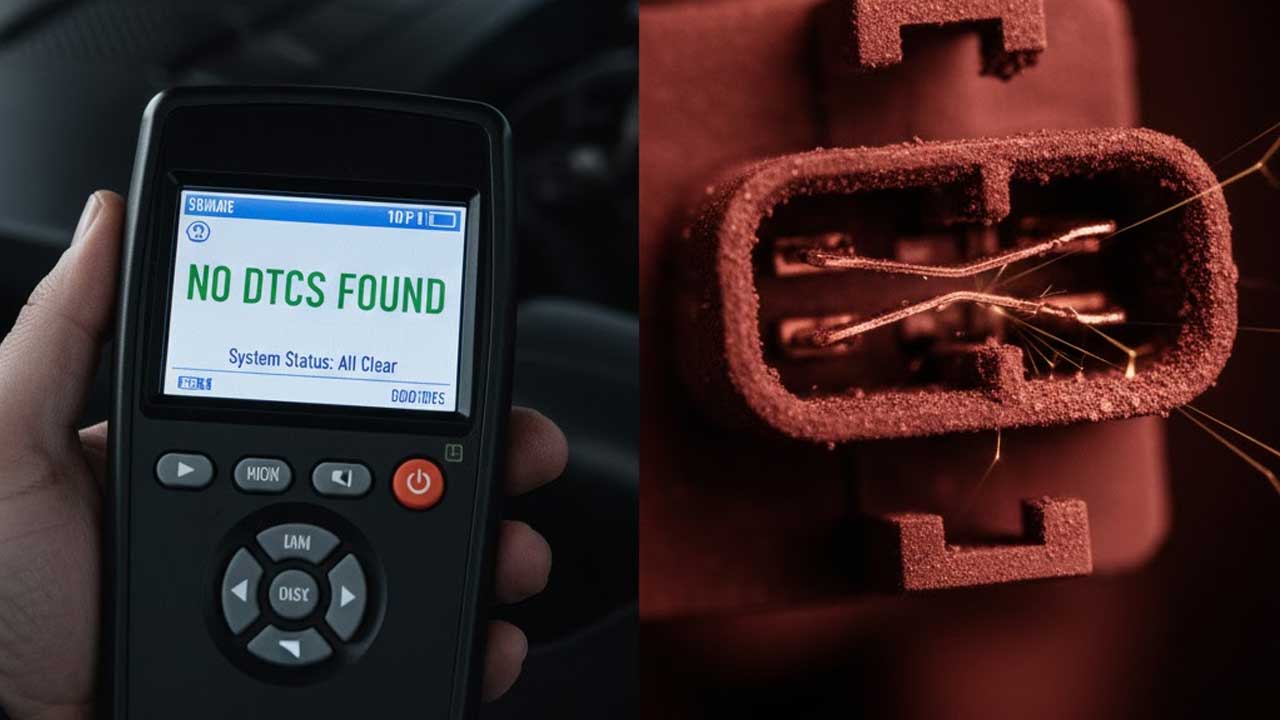

It's the job every technician dreads: the comeback. The customer swears the check engine light flickers on their commute, or the radio cuts out on a specific bumpy road, but it's been running perfectly in your bay for two days straight. You can't replicate the fault. The scanner shows no new Diagnostic Trouble Codes (DTCs). These are electrical ghosts, and they're not just frustrating; they're killers for your cycle time and your shop's reputation.

When dealing with a no-code electrical problem, it's time to put down the scanner and rely on your diagnostic skills. These ghosts often live where the computer can't see them: in the microscopic world of the electrical connector.

Why Your Scanner Can't See Ghosts

A vehicle's computer is designed to set a DTC (Diagnostic Trouble Code) when a sensor reading goes out of range for a specific time. But what happens when a connection fails for just a millisecond? The check engine light flickering might be real, but the event is too brief to be stored as a fault.

An intermittent electrical fault is characterized by its inconsistent nature. It may be caused by factors such as a micro-break in a circuit due to engine vibration, changes in temperature, or moisture. While the scanner is designed to identify consistent failures, these issues often do not present themselves consistently. This is why hands-on automotive electrical troubleshooting is your most valuable tool in diagnosing these problems effectively.

The Connection Point: Ground Zero for Intermittent Faults

Think about an automotive connector: a series of small, metal terminals held in tight contact by spring tension. Add decades of vibration, heat cycles, and potential moisture; this is the perfect environment for subtle failures.

A visual inspection is a good start, but it won't tell the whole story. The most common culprits are often invisible:

- Spread Terminals (Loss of Tension): This is the number one cause of intermittent issues. The female terminal has lost its "grip" on the male pin. It might look connected, but the clamping force is gone, allowing the connection to be broken by the slightest vibration. These loose pins are the ghost in the machine.

- Fretting Corrosion: Over time, micro-vibrations between two terminals can scrape away the protective plating, exposing raw metal. This metal oxidizes, creating a thin, highly resistive layer. It might seem fine to a multimeter on a continuity test, but this resistance can cause phantom issues under an electrical load.

Featured Link: Shop Connector Repair Tools

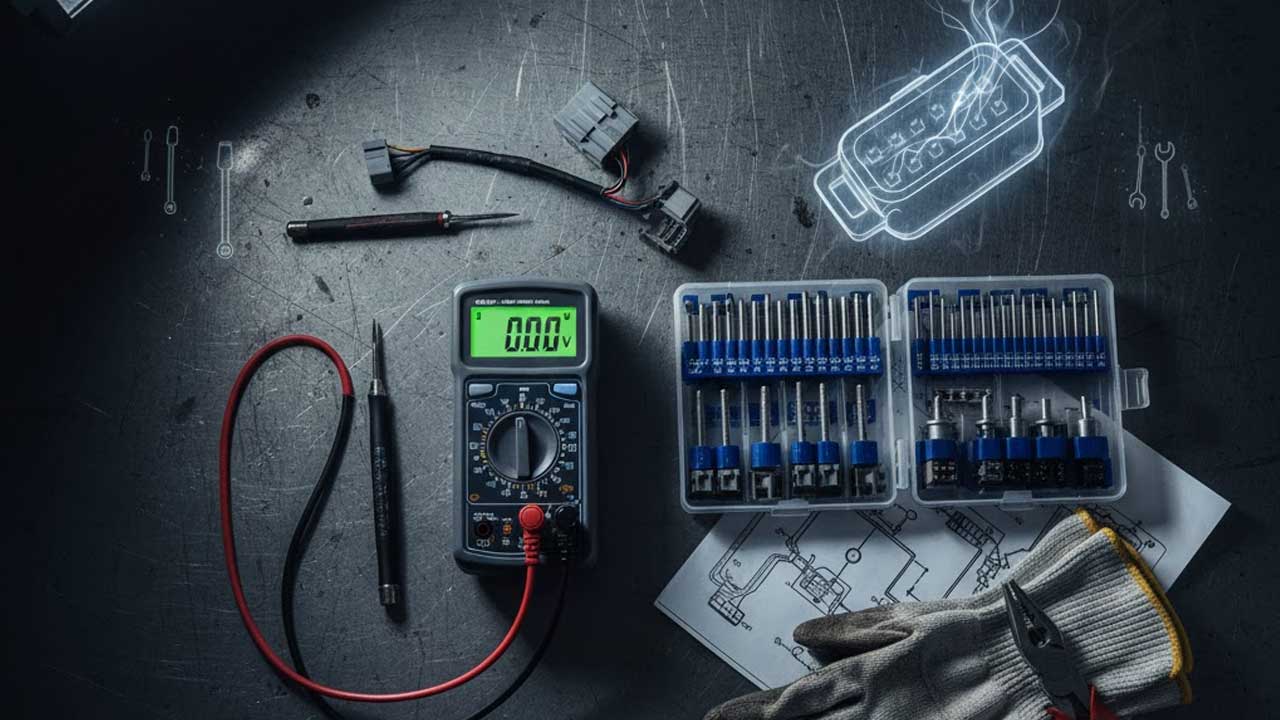

Your Ghost-Hunting Toolkit: Going Beyond the Multimeter

To find these invisible failures, you need to test the connection's integrity physically. Two tests are essential for any serious wiring harness diagnostics.

1. The Loaded Voltage Drop Test: Testing an unloaded circuit for continuity can be misleading. A single strand of copper can show continuity, but can't carry the current needed to power a module or sensor. By testing for a voltage drop while the circuit is running, you force the fault to reveal itself. A reading of more than a few hundred millivolts (0.2V−0.3V) across a connection or wire indicates excessive resistance that needs to be addressed.

2. The Pin-Fit Test (The Ghost Catcher) is the most effective test for finding a bad connection. Pin-fit testing, sometimes called "pin drag," is a physical test of a female terminal's tension.

The process is simple:

- Disconnect the connector you suspect is causing the issue.

- Using a matching male test terminal (or a dedicated terminal testing kit), gently insert it into the female cavity.

- Pay close attention to the feel. You should feel a smooth but firm "drag" as you push the terminal in and pull it out. The tension should be consistent.

- You've found your ghost if the test terminal feels loose or slides in with zero resistance. That terminal has spread and can no longer maintain a solid connection.

The Fix: A Professional Repair, Not a Temporary Patch

Once you've identified a loose terminal, simply trying to "crimp it down" with a pick is not a reliable, long-term repair. The metal's spring memory is gone, and it will fail again.

The only professional solution is to replace the faulty terminal. Using a quality automotive pigtail, you can remove the compromised pin from the connector housing and splice in a new wire with a brand-new, factory-spec terminal. This restores the connection's mechanical and electrical integrity, ensuring the issue is resolved.

Don't let intermittent electrical faults lead to frustrating comebacks. Advanced connector diagnostics, like pin-fit testing, can turn the most elusive electrical problems into quick, accurate, and profitable repairs. Found the problem connector? Our Pigtail Pros can find the solution. Browse FindPigtails.com to connect with a specialist and quickly get the right part in your hands.