Water Damage and Corrosion: Saving Connectors Before It’s Too Late

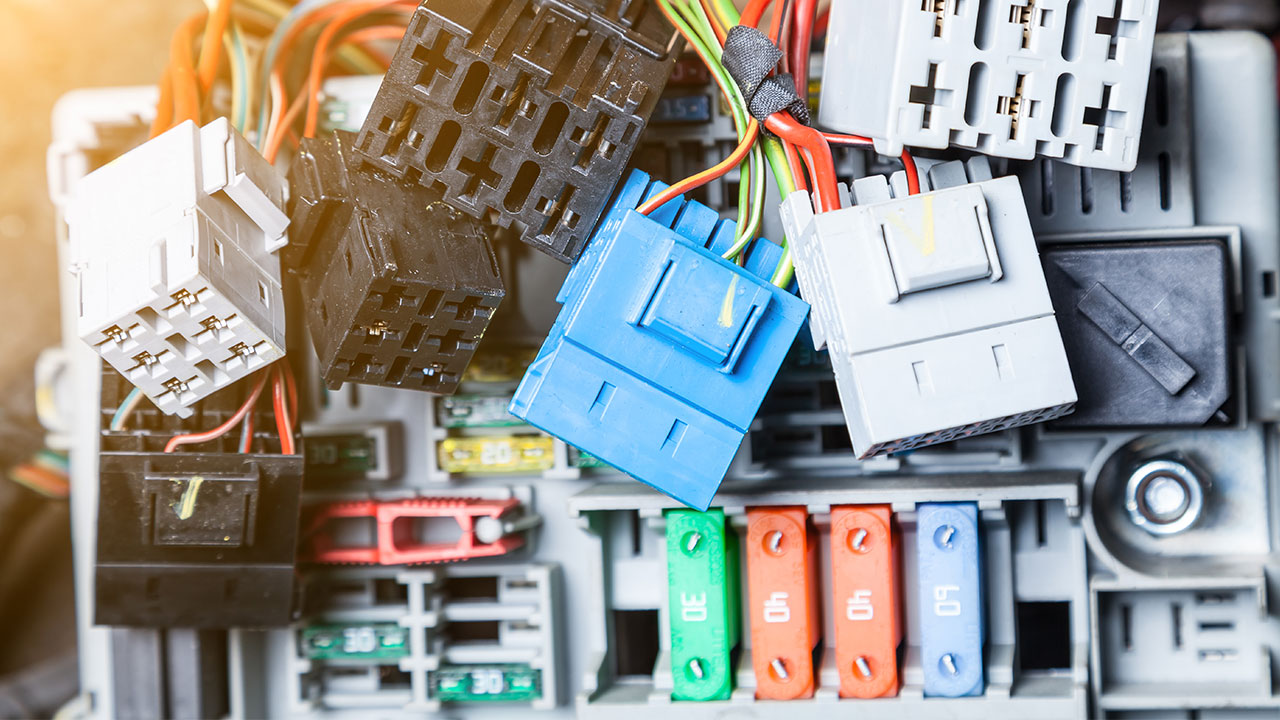

Connectors are the backbone of every automotive electrical system, but are also one of the most common failure points. When water intrusion or corrosion takes hold, it can trigger anything from intermittent warning lights to complete component failure. The problem isn't always obvious, but left unchecked, a compromised connector can turn into a costly repair.

This guide explains how to identify water-damaged connectors, when to repair versus replace them, and the technical considerations every collision or repair technician should keep in mind.

Why Connectors Are Vulnerable

Connectors are designed to serve specific functions; not all are built to withstand exposure to the elements.

- Non-sealed connectors are commonly found in protected areas, like behind dashboards or enclosed modules, where moisture exposure is unlikely. They don't require seals and function trouble-free unless the harness is compromised.

- Sealed connectors are engineered with gaskets or weatherproofing to prevent water, dirt, and salt from reaching the terminals. They are typically found in bumpers, headlight assemblies, undercarriages, and engine bays.

If a sealed connector becomes misaligned, damaged, or improperly reinstalled after a collision repair, its protection is compromised. This is where most water damage issues begin.

Signs of Water-Damaged Connectors

Connectors should always be inspected first when diagnosing electrical issues, especially with exterior components like headlights, fog lights, or side markers. Symptoms to look for include:

- Corrosion on pins: Green, white, or blue powdery buildup indicates oxidation.

- Moisture residue inside housings: Droplets, condensation, or milky films signal intrusion.

- Brittle or discolored wires: Insulation may harden, crack, or change color after water exposure.

- Intermittent electrical faults: Corroded connectors often cause flickering headlights, inoperative side markers, or error codes.

- Heat damage or burning odor: Increased resistance from corrosion can overheat the connector.

By checking connectors in vulnerable locations first, technicians can often save hours of unnecessary diagnostic time.

Repair Strategies: Clean, Replace, or Both

The approach depends on the extent of the damage.

- Cleaning connectors:

- Use electrical contact cleaner and a precision brush to remove mild oxidation.

- Apply dielectric grease after cleaning to protect pins from future corrosion.

- Best for minor issues with intact housing and terminals.

- Pin or terminal replacement:

- Necessary if corrosion has compromised the conductivity of one or more terminals.

- Pin repair kits allow for precise restoration without replacing the entire harness.

- Full connector replacement:

- Required if multiple terminals, seals, or the housing itself are compromised.

- Ensures long-term reliability and eliminates the risk of repeat failures.

Why It Matters to Shops and Technicians

Overlooking a water-damaged connector leads to comebacks and can compromise critical systems such as lighting, sensors, and even safety equipment. Shops that thoroughly inspect connectors in exposed areas during diagnostics save time, protect their reputation, and keep customers safe on the road.

Conclusion: Replace Before It's Too Late

Water damage and corrosion may seem like minor issues, but if ignored, they can undermine entire vehicle systems. By understanding which connectors require seals, carefully inspecting components like headlights and side markers, and applying proper repair strategies, technicians can avoid unnecessary harness replacements and ensure reliable repairs.

At FindPigtails.com, we stock a wide range of OEM-quality automotive connectors and pigtails, including sealed options for exterior components. Whether you need to clean up corrosion, replace pins, or install a new sealed connector, we've got the parts you need to finish the job right.

👉 Shop sealed and unsealed connectors now, and keep every repair watertight and reliable.